Well, if you’re anything like me, your attic is currently a disorganized mess of holiday decorations, old textbooks, and boxes you swore you needed to look through last summer. It’s a vast, wasted space just waiting to be claimed, isn’t it?

I used to think flooring an attic was this huge, terrifying home improvement project—something only seasoned contractors could handle. I mean, climbing around up there, dealing with insulation, worrying about ceiling joists? It seemed like too much hassle, so I just kept tripping over old wiring instead.

But honestly? Once you break it down, laying down an OSB floor in the attic is absolutely doable, even for a weekend warrior. It changed my house. Where I once had a dusty, inaccessible void, I now have proper, usable storage. The feeling of stepping onto a solid subfloor up there, knowing I built it, is something else. It really proved me wrong about my own abilities, and I’m so happy about it.

Let’s dive into exactly how you can turn that messy void into functional square footage using OSB T&G decking.

Key Takeaways

- Always confirm your attic’s load bearing capacity before starting any flooring work.

- Never skip addressing insulation depth and ventilation; you may need to raise the floor.

- Use plenty of subfloor adhesive and leave small gaps between sheets to prevent buckling.

- Learn the safest approach for cutting large sheets in a tight space.

Is it safe to put a floor in my attic and what thickness OSB should I use?

You’re generally aiming for what’s called “light storage” in residential areas. This usually means your joists need to be structurally sound enough to handle 10 pounds per square foot of live load (you standing up there) and 10 pounds per square foot of dead load (the weight of the floor and your stored items). If you aren’t certain, talk to a structural professional. Seriously, don’t guess this part.

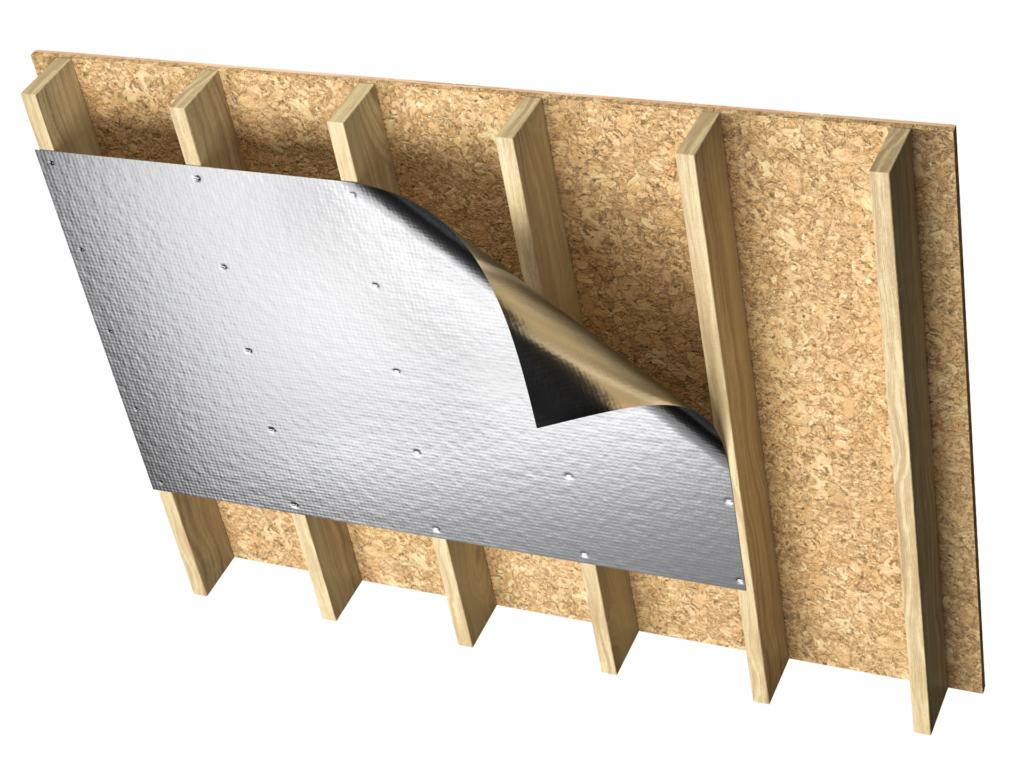

When it comes to the OSB itself, we’re talking about thickness. The common preference for attic decking is tongue and groove (T&G) Oriented Strand Board. Why T&G? Because the edges lock together, spreading the load across multiple joists and making the whole assembly much stronger than simply laying down square-edge plywood sheathing.

For typical 16-inch on center (OC) joist spacing, you’ll want a minimum thickness.

| Joist Spacing (On Center) | Minimum OSB T&G Thickness | Recommended Use |

|---|---|---|

| 12 inches | 1/2 inch (12 mm) | Light, easily distributed loads |

| 16 inches | 5/8 inch (15 mm) | Standard light storage (Most common choice) |

| 24 inches | 3/4 inch (18 mm) | Necessary for greater spans and weight capacity |

We’re focusing on OSB T&G here because it’s generally less expensive than plywood and often available in the convenient 4×8 foot sheets. Just make sure whatever you buy is rated for subfloor use. If you want to dive deeper into structural considerations, especially regarding spans and live loads, check out resources from organizations like the ICC or even reputable university building science departments.

What tools and supplies do I really need before I climb up there?

Here is a list of must-haves for this weekend project:

* **OSB T&G Panels:** Make sure you calculate the square footage you need and then add 5-10% extra for waste cuts.

* **Subfloor Adhesive:** This is crucial. It minimizes squeaks later and adds serious structural integrity. You need PL Premium or something comparable.

* **Construction Screws:** Skip the nails. Use 2-inch or 2.5-inch construction screws. They hold tighter and won’t back out over time. Use deck screws if you want serious grip, but ensure they are long enough to pass through the OSB and sink at least one inch into the ceiling joists.

* **Drill Driver:** A powerful cordless drill driver makes sinking dozens (or hundreds) of construction screws much faster.

* **Circular Saw:** Necessary for cutting panels to fit.

* **Chalk Line and Measuring Tape:** For marking your cuts and keeping your rows straight.

* **Safety Gear:** Gloves, safety glasses, a good dust mask, and long sleeves. Trust me, mineral wool insulation dust is not a fun thing to have on your skin or in your lungs. You can feel that stuff itching for days.

PRO TIP: Use a cordless oscillating tool when cutting smaller, oddly shaped pieces around vents or tight rim joists. It saves you the headache of maneuvering a large circular saw in cramped, dark spaces.

Should I lay OSB directly over joists or raise the floor first?

But here’s the problem: insulation.

If you have modern, deep insulation (like R-38 batts or thick blown-in material), your ceiling joists (usually 5.5 inches tall for R-19) are completely covered. If you lay the OSB directly on top, you’re smashing the insulation flat. When you compress insulation, you drastically reduce its effectiveness. That’s money wasted on energy bills.

Plus, you might block essential airflow. Attics need ventilation to prevent moisture build-up, especially along the eaves. Blocking the soffit vents is a big no-no because it causes humidity and moisture problems, which can damage the sheathing and the OSB floor itself.

To solve this, you need to raise the attic floor above deep insulation.

The simplest way to accomplish this is by adding “sleepers” or new joists perpendicular to the existing ceiling joists, or by building wooden frames or “risers.” Often, adding 2x4s or 2x6s on edge directly on top of the existing framing is enough to lift the floor high enough to clear the insulation and ensure air can move freely beneath your decking. You need to make sure you use construction screws to firmly attach these new risers to the existing joists below.

This is a much better, more strategic way to protect your home’s thermal envelope and air quality.

How do I install tongue and groove OSB attic decking correctly?

You’ll want to start at the wall furthest from your entry point—this allows you to work backward toward the exit, avoiding the need to crawl over sections you’ve already completed.

The first time I tried installing a subfloor, I skipped the chalk line. I just started laying the sheets, thinking I could eyeball it. Oh, man, o man! By the third row, everything was subtly crooked, and nothing was landing properly on the joists. It was a waste, just like other things I start impulsively. It proved me wrong.

Now, I always snap a straight chalk line parallel to the wall where the first row of OSB T&G will begin. This ensures the rest of your installation is square with the existing ceiling joists.

Here’s the basic workflow:

1. **Prep and Placement:** Run a thick bead of subfloor adhesive along the top of the joists where your first sheet will rest. Place the first OSB T&G sheet down, ensuring the groove side is against the wall, leaving about a 3/8-inch gap. This crucial gap allows for expansion, preventing the floor from buckling when humidity changes.

2. **Fastening:** Secure the sheet using your construction screws. Drive screws every 6 inches along the edges and every 12 inches in the field (where the joist passes beneath the middle of the panel). Make sure the heads are flush, not proud, but don’t drive them so deep they break the material surface. You should hear the satisfying whine of the drill driver sinking the screw deep into the wood below.

3. **The Next Sheet (T&G):** For the second sheet in the row, apply a bead of adhesive to the groove of the sheet already laid, then tap the tongue of the new sheet firmly into the groove of the first. You might need a scrap piece of OSB and a hammer to gently tap the long edge of the sheet into place until the joint closes tightly.

4. **Stagger Joints:** When you start the second row, cut the first panel in half. This is non-negotiable! You must stagger the joints between rows, just like brickwork. This distributes the stress and prevents long, weak lines in your floor structure.

My attic joists are not 16 inches on center—how do I floor it?

If you’re dealing with 24-inch spacing, you need to step up to 3/4-inch OSB, as noted in the table above, to maintain adequate load bearing capacity without excessive deflection (sagging).

If your spacing is completely irregular—maybe 14 inches here, 20 inches there—you have a couple of sensible options:

1. **Add Blocking:** You can use dimensional lumber (like 2x4s) cut to fit between the existing joists at regular intervals (16 or 24 inches, depending on your OSB thickness). These “blocks” provide the necessary solid material for your OSB edges to land and secure to, even if the primary joists are unevenly spaced.

2. **Lay New Stringers:** If you’ve already decided to raise the floor to clear deep insulation, you can simply ignore the existing irregular joists entirely and lay your new sleepers (2x4s) perpendicular to them at perfectly standardized spacing (e.g., exactly 16 inches OC). Attach the sleepers firmly, and now you have a perfect, predictable subfloor framework for your OSB T&G decking. This makes the job so much cleaner.

What’s the best way to cut OSB attic flooring pieces when I’m cramped?

You really want to minimize the amount of cutting you do up there. If you know you need 12 panels, and four of them need to be cut lengthwise to fit a 3-foot section, do those rough cuts outside first, while you have space. Get the sheets through the attic access ladder and up into the space.

For cuts that must be made up high (like the final pieces around the rim joists or specific cutouts for pipes or HVAC chases), you have two main rules: safety and dust control.

1. **Minimize Dust:** OSB creates a fine, irritating sawdust. Always wear that high-quality dust mask.

2. **Safety First:** When using a circular saw, use a stable surface. I usually drag a couple of the existing OSB sheets I haven’t installed yet over two secure joists, creating a temporary sawhorse. Make sure the piece you are cutting is well-supported and won’t pinch the blade, or you risk dangerous kickback.

Remember to factor in that small expansion gap (about 1/8 inch to 3/8 inch) along all perimeter walls, just like you did with the first sheet. OSB is known for absorbing humidity and expanding more than plywood, so giving it room to breathe is absolutely key to preventing premature failure and buckling.

Frequently Asked Questions

Does OSB attic flooring cause moisture problems?

If installed correctly, no. However, if you smash down insulation and block ventilation (especially soffit vents), you create a huge moisture trap. Always ensure there is an air gap (typically 1-2 inches) between the top of your insulation and the underside of the OSB decking to allow moisture vapor to escape. If you are concerned about moisture from below, you could potentially use a vapor retarder over the ceiling drywall before laying down the OSB, though this is usually overkill for light storage areas.

What length screws should I use for OSB attic floor installation?

You should use construction screws that are long enough to pass through the OSB T&G material and penetrate the supporting joist by at least 1 inch. For standard 5/8-inch OSB, a 2-inch construction screw is usually sufficient. If you raised the floor using 2×4 sleepers, you’ll need a much longer screw, typically 4 inches, to go through the OSB, the 2×4 riser, and into the original ceiling joist.

How much space should I leave between OSB sheets in the attic?

The tongue and groove system is designed to fit snugly, but you must not butt the end joints (the 4-foot ends) up tight against each other. Leave a small gap—about 1/8 of an inch—at these seams. This is essential for expansion and will stop your floor from warping or lifting during seasonal changes in humidity.

Is it better to use plywood or OSB T&G for attic flooring?

For attic flooring, the difference is usually cost and stability. OSB T&G is typically more budget-friendly. While plywood is often seen as superior for high-moisture environments, T&G OSB is plenty durable for dry attic storage, provided you follow the expansion gap rules. If budget is your primary concern and your attic is dry, OSB is a perfectly plausible choice.

Turning that chaotic space into functional storage is an admirable project. I know you’ve got this.

Are you planning to add proper lighting and maybe even a solid attic access ladder next, or are you just sticking with the floor for now?

Leave a Reply